Acrylic or Polycarbonate Greenhouse

When deciding on a greenhouse the two most popular plastic sheet materials that you will typically be offered as a covering are acrylic and polycarbonate greenhouse. On a percentage-used basis, polycarbonate is the most widely used since it is readily available. A greenhouse company can just buy it easily and have it shipped to the customer with no extra work required. But just because most greenhouse companies use it, does that make it the best choice? Sunglo Greenhouses purposely selected a High Impact Acrylic over 40 years ago to be used in our greenhouse kit designs.

Sunglo High Impact Acrylic – Double Layer

When Deciding Consider These Factors

Light Transmission – The amount of light entering the greenhouse kit is a critical factor for plant health and how quickly plants grow. A rule of thumb used by researchers is that a one percent increase in light equates to a one percent increase in plant growth. This is true for fall, winter, and spring seasons, especially on cloudy days, but in summer there is usually adequate sunlight to keep levels above the saturation point.

Durability – The greenhouse covering has to be able to handle year-round weather, hazards like flying baseballs, and degrading from exposure to the sun.

Longevity – You want to get the most years possible out of the product before it has to be replaced. As a result, provides long-term value and lowers the environmental impact by reducing waste.

Insulation (R-value) – How much heat retention will the greenhouse covering provide is an important consideration if you plan to use it all year round. Insulation is rated using R-value. The higher the number the more insulated the material will be.

Why Do Sunglo Greenhouses Use Acrylic?

We get asked this question often because the greenhouse covering used by other manufacturers is polycarbonate. Polycarbonate is typically used because it is a convenient choice rather than considering the factors mentioned above. Polycarbonate is readily available and produced in standardized dimensions. Sunglo uses acrylic that is custom-cut and formed specifically to meet our Sunglo Greenhouse kit design standards. We believe using acrylic on our greenhouses undoubtedly offers the best solution for gardeners so they can successfully grow all year round.

Light transmission (LT)

Sunglo Greenhouses allow in to 90% Light Transmission

As a grower, you want the most light possible inside your greenhouse kit to produce the healthiest and quickest crop. This is especially true if you plan to grow through winter or start seedlings in early spring when the days are short. Acrylic has higher light transmission than polycarbonate. In fact, Sunglo Greenhouses High Impact Acrylic is rated at 90% Light Transmission in contrast to the 6mm twin wall polycarbonate at 82%. The light transmission increases to 14% more light using acrylic when compared to triple wall polycarbonate (90% vs 76%).

Durability

Sunglo Greenhouse Kits uses High Impact Acrylic sheets making them able to better withstand impacts due to extreme weather events or even the occasional baseball (see a video showing the impact test). A single layer of acrylic has an impact resistance that is 17x that of glass but Sunglo uses an exclusive double wall High Impact Acrylic design which adds even more protection to withstand the abuse of an outdoor environment. Sunglo greenhouse kits are the best heavy-duty greenhouse kits available.

Longevity

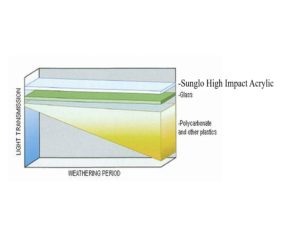

Sunglo Greenhouse High Impact Acrylic is UV Stable so it doesn’t yellow as quickly as polycarbonate.

Acrylic is naturally UV-stable so we don’t have to apply coatings to protect it from breaking down in the sun. Polycarbonate, on the other hand, needs a protective coating for UV protection but even then it will start hazing & yellowing over time which starts reducing Light Transmission (LT).

We mentioned earlier the importance of keeping high light inside the greenhouse is beneficial. Polycarbonate loses anywhere on average 1-2% light per year from UV degradation, but Sunglo acrylic is less than 1%. The average life of a polycarbonate greenhouse panel is 15 years because the light transmission will have decreased approximately to . Now compared to a Sunglo Greenhouses High Impact Acrylic you can expect 25+ years with minimal light loss and no yellowing. We have Sunglo customers who have owned their greenhouses since the 1990s that can attest to this fact and are still growing under the original greenhouse covering. Sunglo High Impact Acrylic panels have a 10-Year Limited warranty.

I have had more than one Sunglo Customer tell me they have owned their greenhouse for over 25 years the acrylic has not yellowed or hazed and it looks like it is still brand new by power washing it clean every three months.

Given the fact you do not need to replace the covering as often versus polycarbonate, there is less impact on the environment with the disposal. It is also important to note that acrylic is recyclable whereas polycarbonate is not.

Insulation (R-value)

Growing efficiently in winter inside a Sunglo Greenhouse.

Acrylic can be custom formed and molded. Sunglo created a double-wall design called the “Therma-Truss”. The two layers of High Impact Acrylic form a 1.37-inch dead air space giving a Sunglo Greenhouse a higher R-value of 3. The larger the R-value means it can better keep out the winter cold or summer heat. Compared to polycarbonate greenhouse panels that are typically .25 to .625 inches thick. For example, a 6mm polycarbonate greenhouse panel has an R-value of 1.54.

Sunglo offers an optional Winter Package that includes a 3rd layer of acrylic which increases the R-value above 3 helping keep your greenhouse more efficient in the cold winter months and reducing heating costs. I would consider this option if you are planning to actively grow during the winter months to help keep your heating costs down when winter greenhouse gardening. Sunglo Greenhouse Kits are the best greenhouse for winter.

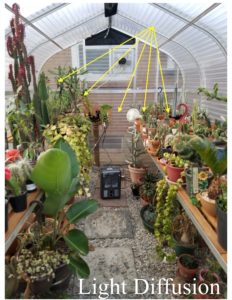

Light Diffusion

Diffused light is formed when the direct rays from the sun are scattered by Sunglo’s double-wall High Impact Acrylic design.

Additionally, the double-wall acrylic design scatters the light evenly throughout the greenhouse providing maximum light dispersion across the entire space. Diffusing the light eliminates shadows allowing plants to grow great no matter where they are located inside. There are many benefits provided by diffusing sunlight from increased photosynthesis, reduction in sun scorching, and reduced fungal & pest pressure.

Easy Maintenance

Sunglo High Impact Acrylic panels are easy to maintain and replace. Our Panel Strip Locks allow you to quickly install or remove the greenhouse roof acrylic panels for cleaning or replacement. Sunglo customers can find both the pre-cut Inner and

Panel Lock Strips can be easily removed to access the High Impact Acrylic panels for cleaning or maintenance.

Outer High Impact Acrylic panels on our website. We can ship the panels out quickly ensuring quick repairs.

Why Not Acrylic for your greenhouse?

The two most popular plastic sheet materials for covering a greenhouse are Acrylic and Polycarbonate. Sunglo Greenhouses chose High Impact Acrylic over 40 years ago because we believe it offers an unsurpassed combination of durability, longevity, light transmission, and overall value! By using acrylic in our Sunglo Greenhouses design we have created a greenhouse that is appreciated by professional gardeners and hobbyists alike.

We hope this information helps you better understand why Sunglo has chosen to use acrylic in our greenhouse design. If you need additional information regarding our greenhouse kits or would like to speak with someone who owns a Sunglo Greenhouse, contact us at sales@sunglogreenhouses.com or by calling (720)-443-6761.

Sunglo Greenhouse is located in Crested Butte, Colorado